Alfa Laval

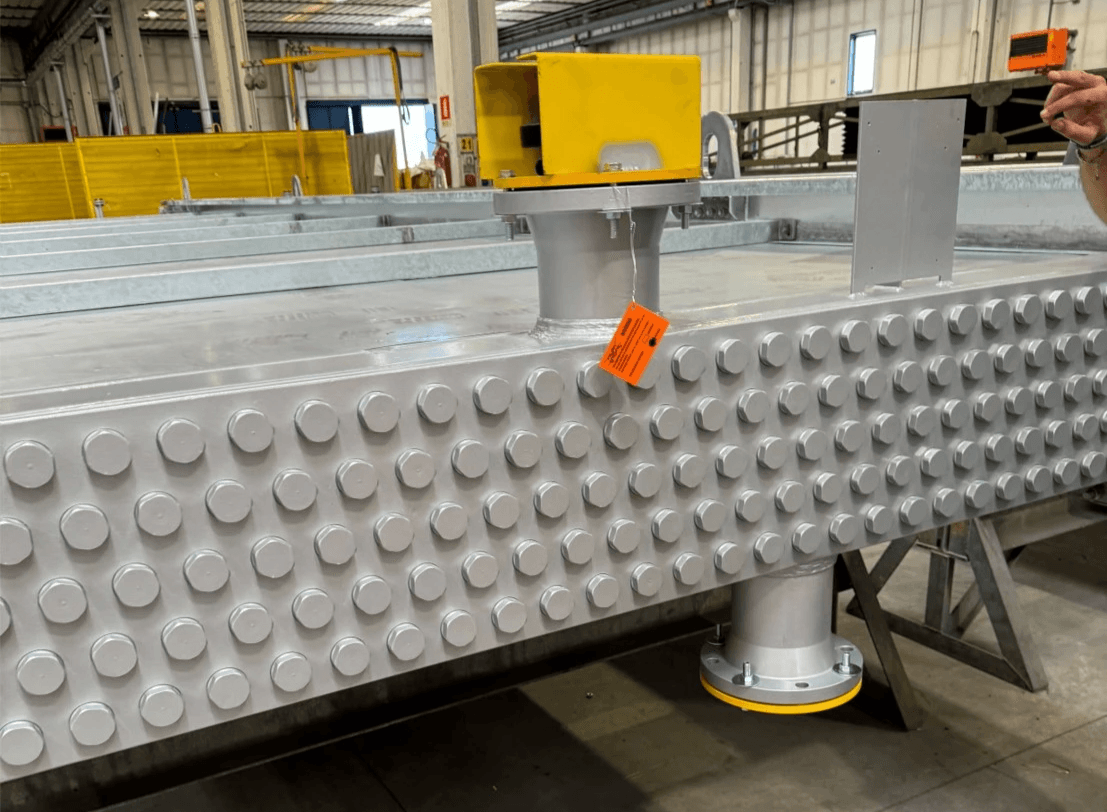

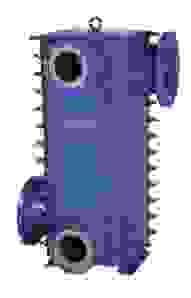

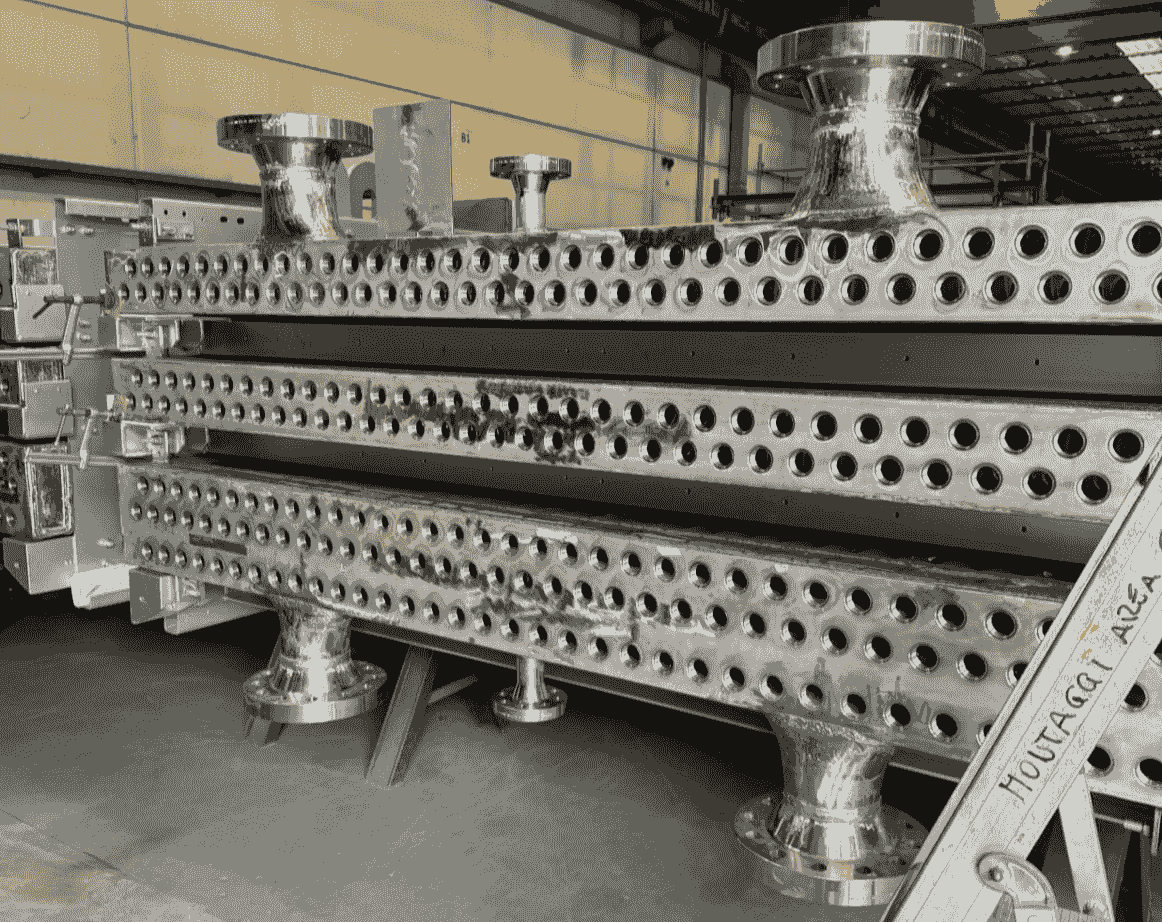

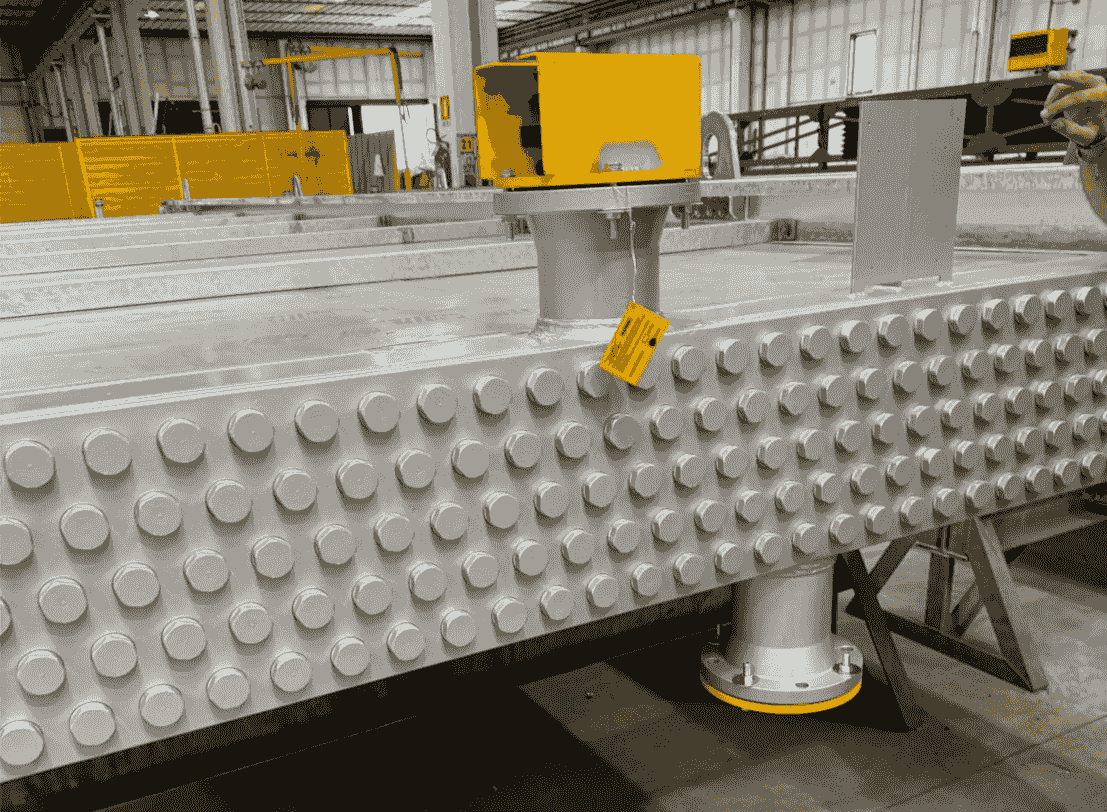

Compabloc Plate Heat Exchanger

The Alfa Laval Compabloc range provides compact and efficient heat transfer for a wide range of clean and dirty process duties.

Full and easy cleanability on both circuits makes it the most service friendly welded heat exchanger on the market.

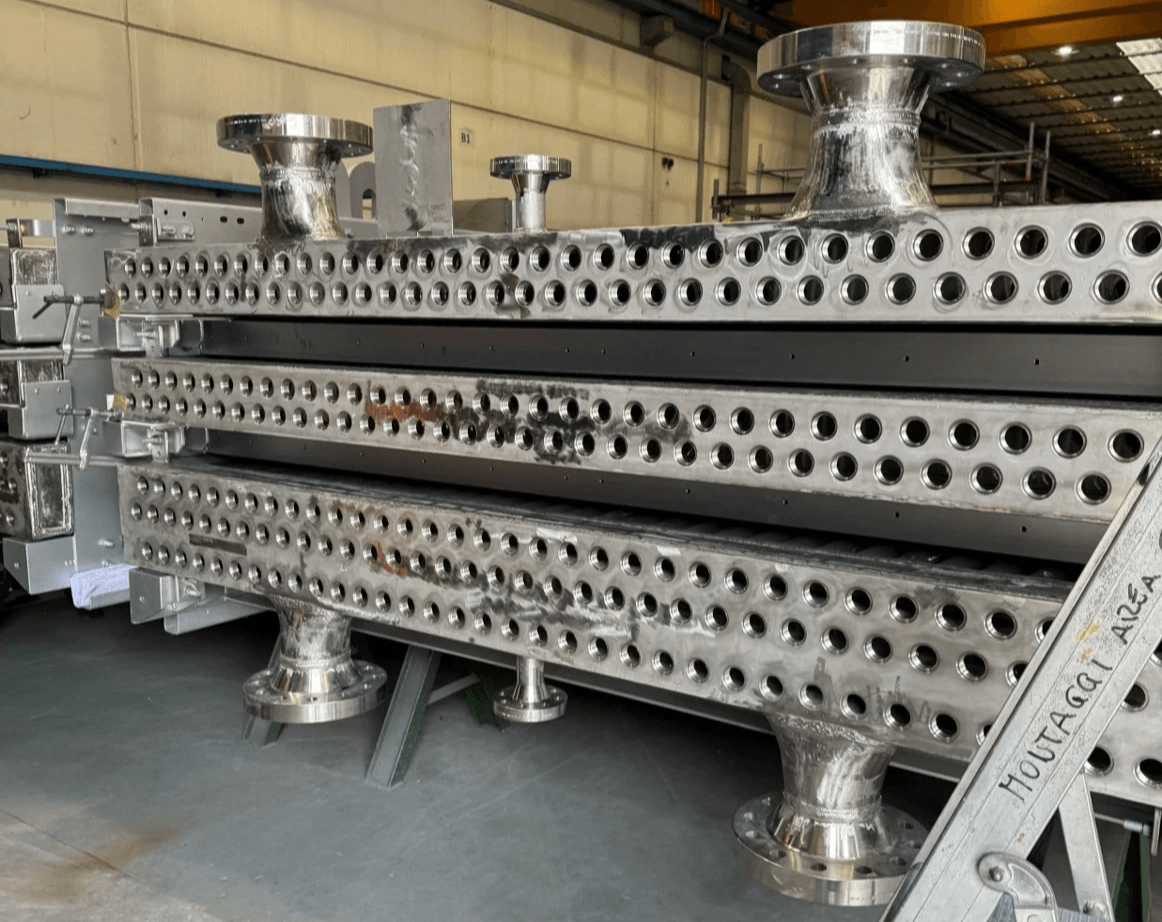

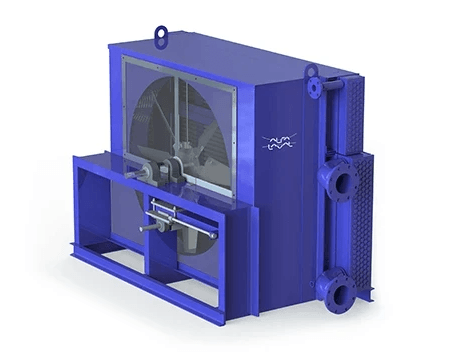

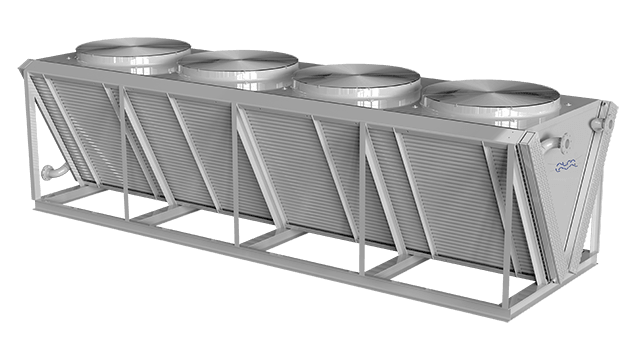

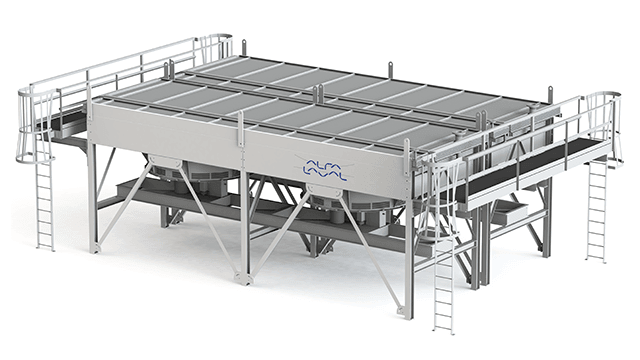

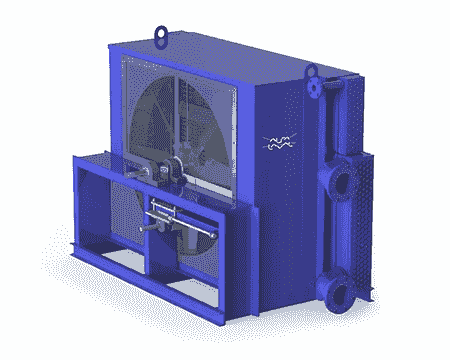

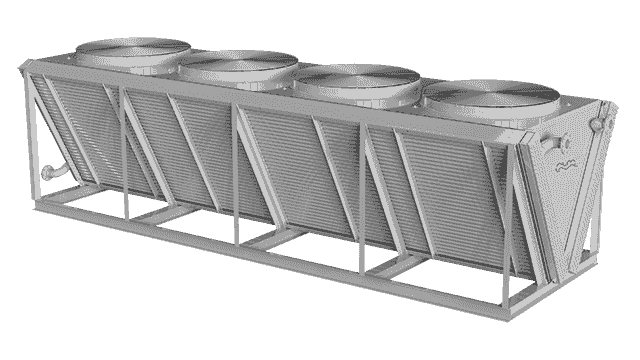

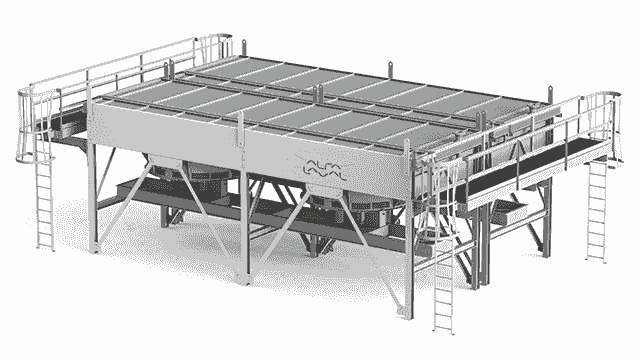

Alfa Laval Olmi

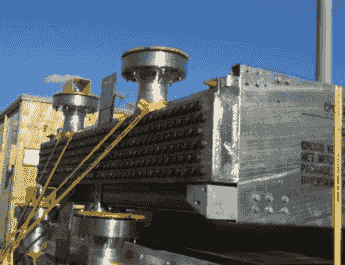

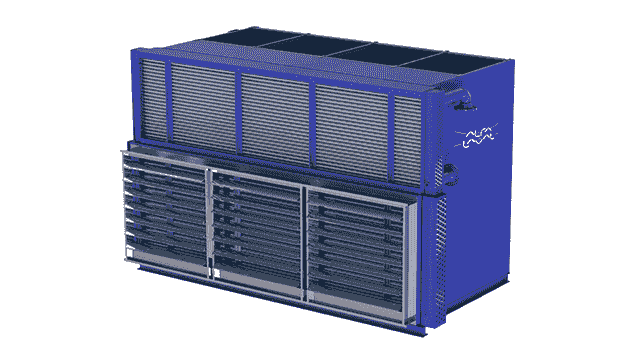

Air-cooled heat exchangers

With an Alfa Laval Olmi finned tube air heat exchanger you get a robust cooler that will deliver high performance for many years to come. Our product range covers most applications in the oil & gas, petrochemical and power industries. We supply both standardized and fully customized, engineered-to-order solutions. Thanks to their flexible designs, we can configure our heat exchangers to match your specific operating conditions, ensuring reliable operation, low operating costs and high performance.

Alfa Laval finned tube air heat exchangers are built for reliable operation, year in and year out, in the most demanding applications. We have supplied air-cooled heat exchangers for upstream, midstream and downstream applications for over 50 years, and we know what it takes to ensure high uptime. Based on your specific operating conditions, we provide a customized, high-quality solution with low CAPEX and OPEX.

ACE Model A

ACE Model J

ACE Model C

ACE Model V

ACE Model E

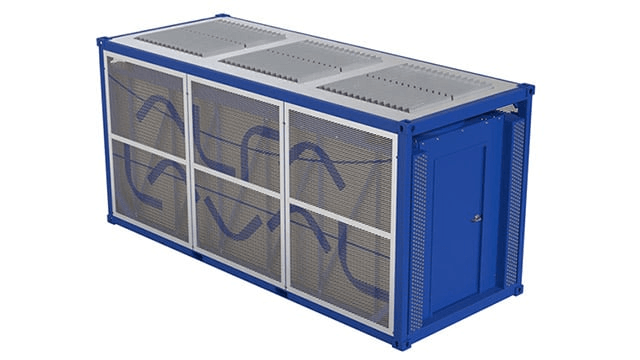

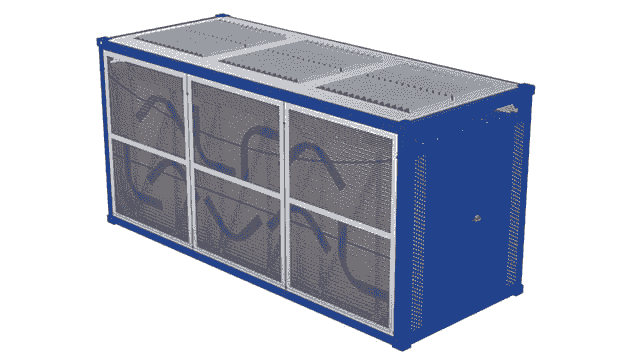

Cooling Pod

UOP

Zeolite MolSieve and Adsorbents

Adsorbent Solutions in Refining / Separation and Purification Solutions

Extending catalyst lifespan, protecting equipment, and ensuring product quality standards are met.

The UOP active alumina adsorbent product portfolio helps improve operational efficiency by removing various contaminants, including: Hydrogen sulfide, Mercaptans, Carbon dioxide, Carbonyl sulfide, Hydrogen fluoride, Chlorine, Mercury, Arsenic, Oxidizers and Water.

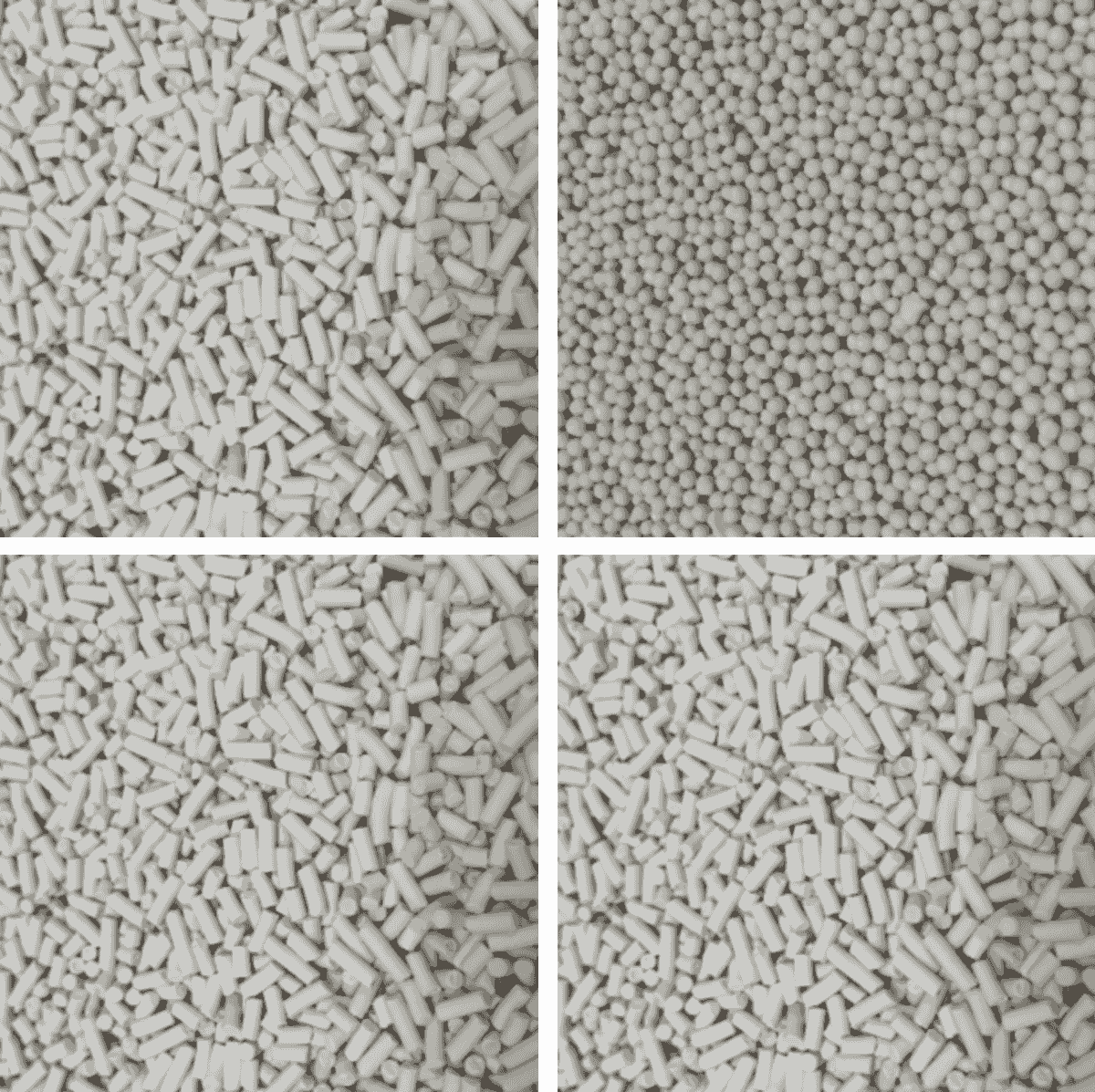

Christy Catalytics

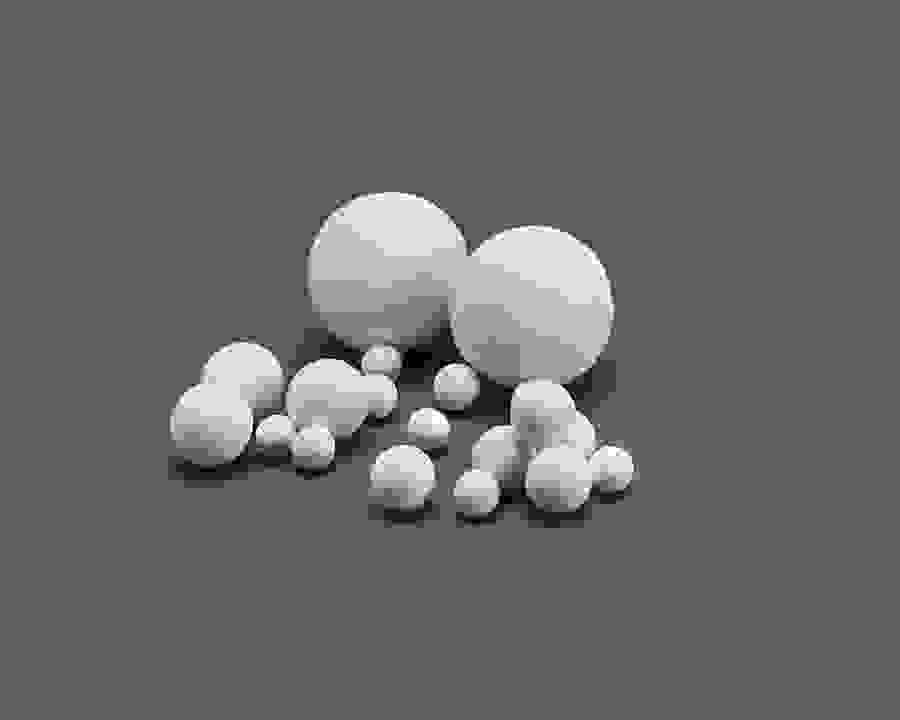

Ceramic Balls

T-38 PROX-SVERS® Ceramic Balls

- Manufactured in Christy’s Crooksville, OH manufacturing plant

- Aluminacontent of 38%, higher than all other vitrified support ballson the market. This allows for a higher maximum use temperature (2500 F/ 1370 C)

- Best strength and impact resistance of any vitrified inert on the market

- Very low porosity and excellent abrasion resistance

- Ball is notfully vitrified, aids in pressure shock resistance

- Formula includesadditive that acts asa crack-stopper

- Meets specifications for UOP’s ICB (InertCeramic Ball) Type 1 and Type 2

- Approved by Topsoe, KBR and ExxonMobile

T-86 PROX-SVERS® Ceramic Balls

- Silica alumina ball (18-28%)

- Fully vitrified ceramic support ball (glassyinterior)- allows for very high-pressure shock resistance

- Appropriate forapplications with modest temperatures (1800 F /982 C )

- Has very low permeability and excellent abrasion resistance

- Approved by key refinery technology licensors (ex. Honeywell UOP, Topsoe, ExxonMobil, Axens)

- Meets specifications forUOP’s ICB (InertCeramic Ball) Type 1 and 2

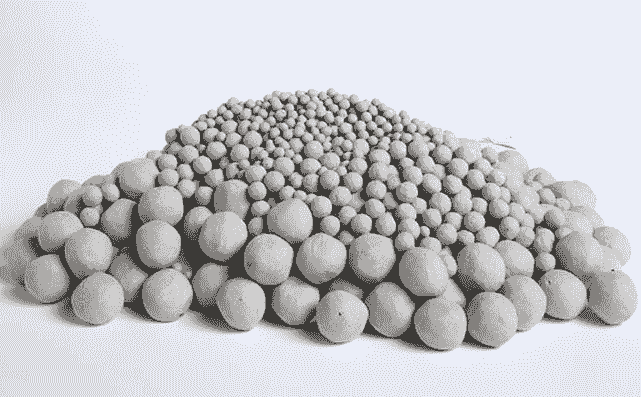

Alumina Balls

T-99/ 99.5 PROX-SVERS® alumina balls

- High purity alumina support ball

- Manufactured bysintering alumina

- Approved by key refinery technology licensors

(ex. Honeywell UOP, Topsoe, ExxonMobil, Axens) - Approved by key petrochemical technology licensors

(ex. Lummus Technology, TechnipFMC-Badger) - Meets specifications for UOP’s ICB (Inert Ceramic Ball) Type 3.

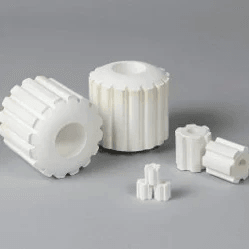

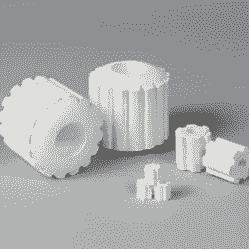

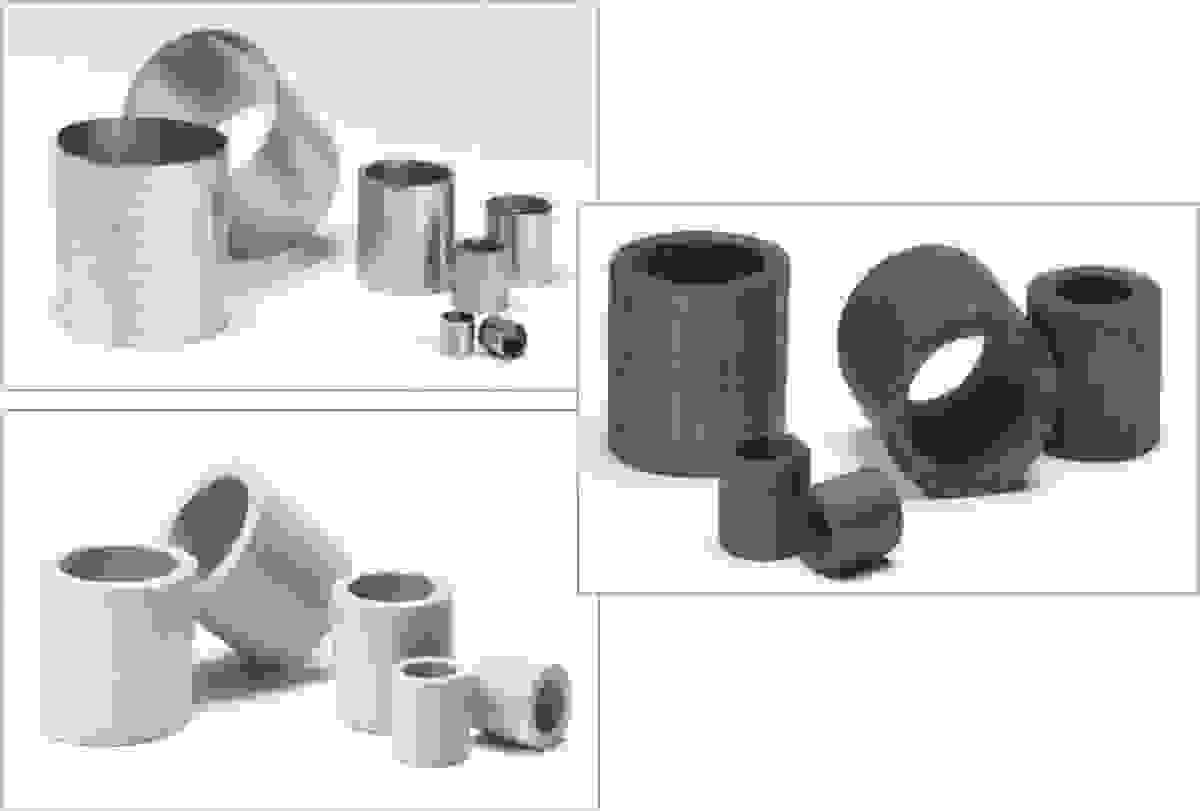

Cata-Cogs

- High Capacity, Low Pressure Drop Bed Support Media, can be used as both hold down and bed support.

- Available in both alumina and ceramic

Christy® Pak Raschig Rings

- Original Random Packing shape

- Developed by Fritz Raschig

- Cylindrical Shape [Length equal to O.D.]

- Materials of Construction: Carbon/ Metals/ Ceramics/ Thermoplastics

Christy® Pak Arch Saddles

- Direct equivalent of Koch-Glitsch IMTP®

- 3rd generation packing

- High capacity, low pressure drop

- Widespread usage in petrochemicals industry worldwide

- Available in a variety of metal materials of construction

- High efficiency in a wide variety of processes (stripping, distillation, absorption)

- Commonly used packing → in stock

Hyangtec Global Corporation All Rights Reserved. ©2025